Walking into a spice processing factory in Huaihua, Hunan, the unsalable products piled up in the warehouse once made the factory director Zhou Wei sleepless all night. Traditional plastic packaging of star anise, cinnamon and other marinade materials, due to poor sealing, cause the aroma to volatilize, and the damage rate in e-commerce transportation is as high as 15%. Until the introduction of non-woven packaging machines last year, this dilemma was completely broken-now their products have not only entered high-end supermarkets, but also become the designated supplier of Internet celebrity hot pot brands.

"When customers complained about packaging powder leakage, I wanted to personally wrap each bag with tape." Zhou Wei recalled with a wry smile. The traditional manual sealing hot press is inefficient, can only process 200 bags per hour, and the seal is prone to moisture and cracking. What's more difficult is that young consumers' doubts about the environmental protection of plastic packaging have caused the product to be frequently unpopular on supermarket shelves.

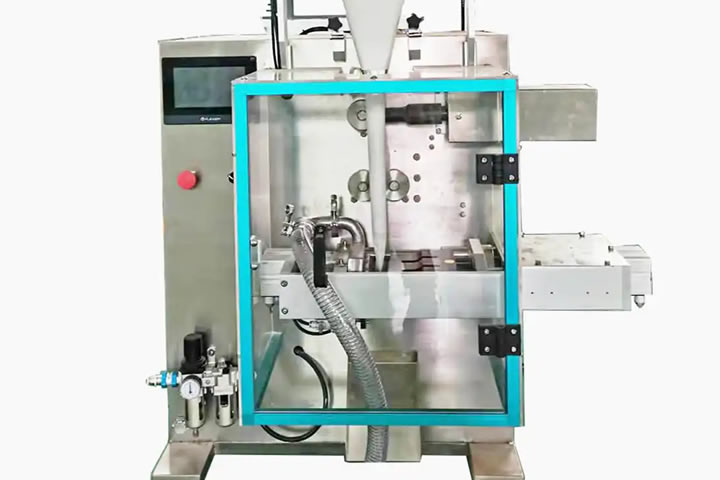

The turning point came in the spring of 2023. At the industry exhibition, Zhou Wei was attracted by the demonstration of the non-woven packaging machine at the ply-pack booth: the equipment uses ultrasonic welding technology to accurately fuse two layers of non-woven fabrics, without the need for glue or chemical adhesives throughout the process. "During the sealing strength test, our bag filled with 500 grams of cinnamon powder fell from a height of 3 meters without breaking." He immediately decided to introduce the equipment.

Technology landing: 72-hour production line transformation

On the day the equipment arrived at the factory, the ply-pack engineering team moved in simultaneously. The transformed production line showed amazing adaptability:

• The automated production system realizes unmanned operation of the entire process of feeding, bag making, filling, and sealing, and the efficiency is increased to 1,200 bags per hour;

• The ultrasonic welding module automatically adjusts the energy output according to the size of the spice particles to avoid high temperature from destroying the essential oil components of the plant;

"The most surprising thing is the innovation of the packaging form." The production supervisor pointed to the newly launched three-dimensional triangular tea bag and said. With the help of the quick-change mold function of the non-woven packaging machine, the factory has developed a marinade bag that can be directly put into boiling water, solving the pain point of consumers needing to unpack the package. This product set a record of selling out 3,000 orders in 5 minutes during live streaming.

Products with matte texture non-woven packaging soon showed their advantages in supermarket channels. Consumers can scan the QR code on the package to view the carbon footprint data of the entire chain from raw material planting to packaging production. "Some customers specifically left a message saying that they are willing to pay 10% more for environmentally friendly packaging." The head of e-commerce operations showed the backstage evaluation.

The more far-reaching impact occurred at the supply chain end. Zhou Wei's factory has now become a local environmentally friendly packaging demonstration unit, attracting many organic farms to actively seek cooperation. After an inspection, the purchasing director of an international chain restaurant said: "From the workshop dust removal system to the packaging biodegradable certification, the upgrade of this factory is exactly the sustainable partner we are looking for."

Standing in the brand new automated workshop, Zhou Wei watched the non-woven packaging machine spit out the finished product smoothly, and finally smiled. Spices that were once unsalable are now packed in breathable and moisture-proof non-woven bags and are being shipped across the country through logistics networks. This transformation, triggered by a piece of equipment, not only saved a company, but also proved the commercial value of combining environmentally friendly packaging with technological innovation.