Last month, our engineering team just came back from the northwest with two boxes of "special souvenirs" sent by a local mineral water factory - limited edition mineral water with "Thanks for solving a ten-year problem" printed on the bottle. This customer has used an old production line for eight years, and finally got a new life through the transformation of our bottled water labeling and packaging line.

Old production line encounters new problems

The original labeling machine of this customer often has skewed labels and bubble wrinkles, especially when producing different bottle types, it takes most of the day to debug. When talking about this, the factory manager, Lao Li, shook his head: "Last year, when we launched the new conical bottle, the labeling pass rate was stuck at 70%, and the returned boxes in the market were piled higher than people." Our field investigation found that the traditional equipment has a single positioning method, and it is "confused" when encountering special-shaped bottles, and the conveyor belt and the labeling machine speed are not matched enough.

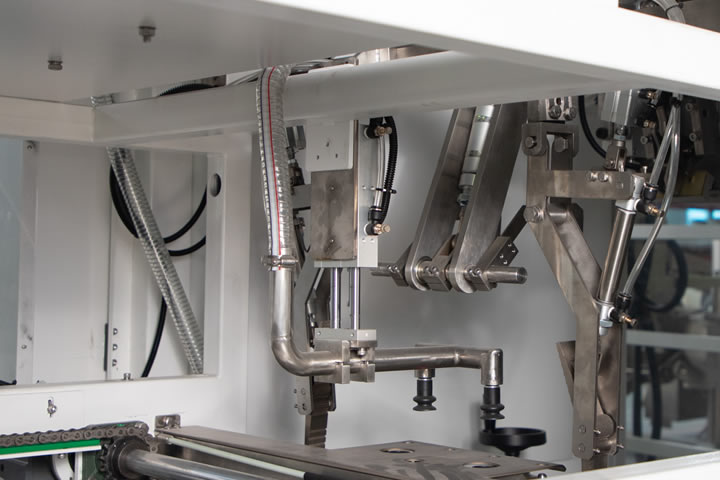

Equip the packaging line with "fire eyes and golden eyes" The core of the transformation plan is to upgrade the visual positioning accuracy. We installed three sets of high-sensitivity sensors at the key positions of the bottled water labeling packaging line, combined with the self-developed image processing algorithm. Now, whether it is a round bottle, a square bottle or a wavy bottle, the 360-degree contour scan can be completed instantly after entering the label. On the day of debugging, the operator Xiao Ma stared at the conical bottle that had just been pasted and exclaimed: "This label fits like it grows on the bottle, and the bubble holes are perfectly aligned!" The secret of one-touch switching The ability to adapt to multiple bottle types is the highlight of this transformation. Engineers redesigned the fixture quick-change structure. To switch between different specifications of bottles, only the positioning module needs to be replaced, and the main transmission mechanism is completely universal. The customer's technical supervisor did the math: "It used to take three hours to stop the line to change production, but now it can be done in 20 minutes, and the production capacity can be adjusted more flexibly during the off-season and peak season." What's even better is that our high-speed labeling system can automatically identify bottle types, and there will be no "mistaken labeling" during mixed production.

The balance between speed and precision

While maintaining labeling accuracy, the increase in the speed of the entire line is another major breakthrough. By optimizing the acceleration curve of the conveyor belt, we have achieved "flexible hand-in-hand" between the filling section and the labeling section of the bottled water labeling packaging line. After a trial, a customer in Shanxi reported that under the same equipment layout, the hourly output increased by nearly 40%, and the bottle breakage rate decreased significantly. "It's like changing a two-way two-lane road into an overpass, which runs fast and does not cause accidents." The production manager's metaphor made the entire visiting group laugh.

Practical combat tests hard work

The transformed production line has undergone rigorous testing: continuous operation in a cold storage environment of minus 5 degrees, intensive production during the rainy season with 85% humidity, and rapid switching of labels of different materials (from PVC to biodegradable film). What surprised customers the most was that the compatibility issues of old equipment that they were worried about were perfectly resolved by our packaging line integration solution - the original filling machines and palletizers were all seamlessly connected, truly realizing the "old clothes are cut again".

At present, this brand-new bottled water labeling and packaging line can handle 200,000 bottles of production capacity per day, and the labeling qualification rate is stable at more than 98.5%. Looking at the smoothly running production line on the monitoring screen, Director Li patted the equipment and said: "If I had met you ten years earlier, I could have saved enough waste bottles in my warehouses to build an office building!"

The seventh-generation labeling system that our factory is developing has entered the actual testing stage. It can not only handle liquid products, but also be compatible with new fields such as sauce bottles and cosmetics. If you are having a headache with labeling special-shaped bottles, or want to tap the potential of old production lines, welcome to our experience workshop. Let every bottle of water wear a perfect "coat", this is our specialty!