Last month, when I visited a customer, I passed by the workshop of a food factory in North China. Through the glass, I saw more than a dozen of our fully automatic paper packaging machines spitting out mooncake gift boxes. I thought I had entered a printing factory. The workshop director Lao Liu who led the way patted me on the shoulder and laughed: "Thanks to your equipment, we didn''t work overtime during the Mid-Autumn Festival this year!" This is more enjoyable than drinking ice soda in the dog days of summer - our machines really helped customers withstand the tough battle.

A "sweet trouble"

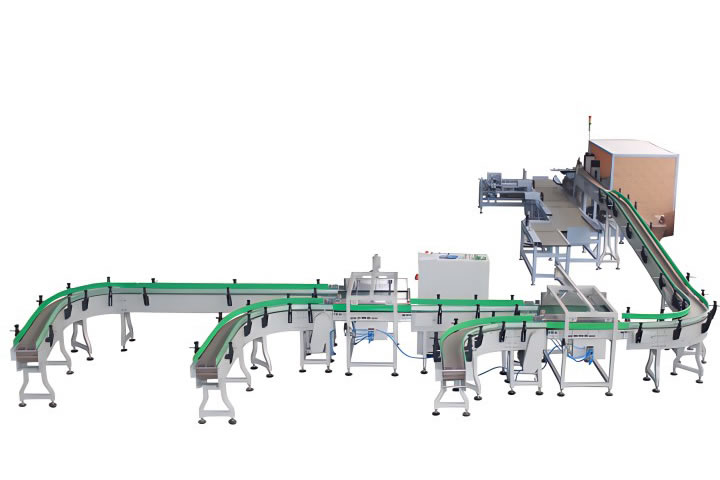

This time last year, this factory was not so leisurely. They focus on traditional pastries, and the speed of hand-wrapping gift boxes can''t keep up with the speed of live broadcasting. The factory manager came to our factory with a stack of wrinkled complaint forms, pointing to the five-layer mooncake box in the sample room and shaking his head: "Manually folding this kind of three-dimensional box, the master can only wrap 800 at most a day, and the machine has to stop working for half a day to change the model. Do you have any tricks?" Our engineer moved a fully automatic paper packaging machine to demonstrate on the spot. The cardboard is "eaten" from the feed port, and it becomes a gift box with clear edges and corners in less than 30 seconds. It can also automatically adjust the amount of glue to adapt to different paper qualities. The factory manager stared at the right angles of the finished box for a long time, and suddenly took out his mobile phone to record: "Can this folding accuracy be filmed for the young people in the e-commerce department to see?" Flexible production shows its magic power The day when the equipment was really pulled into the customer''s workshop, I finally saw what "actual combat test" is. Their gift boxes have six sizes, and they have to switch at any time according to orders every day. We installed an intelligent memory module for the fully automatic paper packaging machine in advance, and the operator can call up the preset parameters with two clicks on the touch screen. The most amazing thing is the special-shaped box adaptation function. There was a lotus-shaped gift box that needed to be punched on the edge to pass a ribbon. We adjusted the mold overnight, and the hole position error was controlled within half a millimeter when the machine was tested the next day.

When the customer opened the video for acceptance, the machine was just wrapping the eight-treasure rice gift box. Watching the paper box change from a flat plate to a three-dimensional one like magic, the other party’s purchasing manager shouted directly: "This machine is more efficient than my mother-in-law in wrapping zongzi!"

Energy saving and consumption reduction became an unexpected surprise

After the equipment was in operation for half a month, the lady from the Finance Department came to us with the electricity bill: "With the same output, how come the electricity bill is less?" We had prepared for this matter - the variable frequency drive system of the fully automatic paper packaging machine is not a decoration. It automatically enters the power saving mode when in standby mode, and the transmission parts also use self-lubricating materials. Later, the customer calculated the account, and the electricity bill and glue loss saved alone were enough to buy a new equipment in half a year.

What surprised the customer even more was the scrap rate. In the past, there were always 10% defective products in manual box folding. Now that the fully automatic paper packaging machine is running, at most two or three slightly defective products can be picked out from 1,000 boxes. The quality inspection team leader joked: "If this continues, our team will have to change their careers to become equipment maintenance personnel!" From "firefighting" to "prevention" Last month, the customer suddenly placed an urgent order, requiring the delivery of 50,000 sets of newly designed hexagonal gift boxes within three days. If it were in the past, the workshop director would be so anxious that his mouth would be foaming. Now it''s good - the engineer remotely updated the program package for the fully automatic paper packaging machine, and the workshop workers learned how to operate it by following the video for half an hour. On the day of delivery, the factory director specially sent a video of the workshop: rows of royal blue gift boxes on the assembly line marched forward, as neat as the National Day parade. Recently, they have figured out a new way to play and connected our equipment to the MES system. The production progress and fault warnings can all be seen on the mobile phone. Once the main motor bearing temperature was abnormal, before the customer reported it, our after-sales team was already on the road with the accessories. Case Inspiration:

This project makes us more convinced that the fully automatic paper packaging machine should not be a cold iron lump. Watching the customer go from being busy and flustered to being calm and relaxed, and listening to the regular sound of equipment running in the workshop replacing the previous urging and shouting, this is what a smart packaging solution should look like.

If your production line is also experiencing similar "growing pains", welcome to our workshop for practical experience. Touch the finished box just out of the fully automatic paper packaging machine, and see how flexible production can simplify complex processes. I guarantee you will be impressed: it turns out that machines can really understand people''s hearts!