A large copper mining company in South America processes more than 2 million tons of ore annually. Its bulk ton bag packaging line has long faced two major problems: ¢Ù Excessive dust concentration in the mining area leads to frequent equipment failures, with an average daily downtime of more than 4 hours; ¢Ú Traditional packaging lines rely on manual calibration, with an error rate of up to 8%, and trade disputes caused by weight discrepancies cause losses of more than 500,000 US dollars each year.

At the beginning of 2022, the company launched a tender for packaging line upgrades and clearly put forward three major requirements:

. The explosion-proof level of the equipment must meet the CT6 standard and adapt to high dust and high humidity environments

. The packaging accuracy error rate is controlled within 0.5%

. The transformation period does not exceed 60 days to avoid affecting the fulfillment of export orders

Ply-Pack Customized Solution

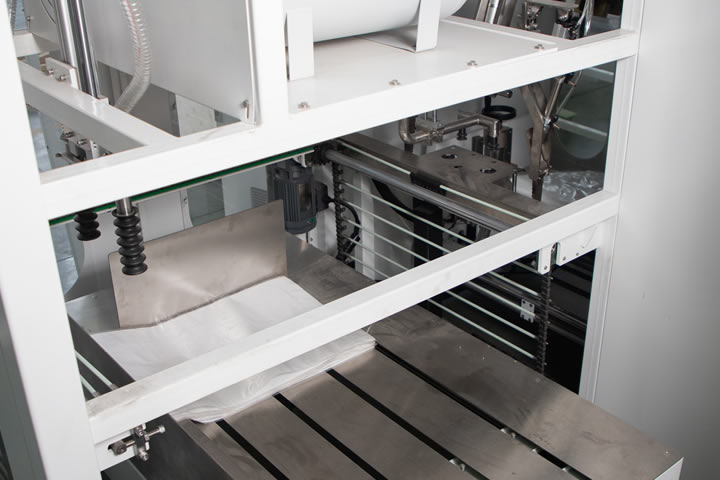

Smart Packaging Equipment Reconstruction

.

· Military-grade explosion-proof box design is adopted, and the core electrical components are ATEX certified

· Dust concentration real-time monitoring module is implanted, and the negative pressure dust removal system is automatically started when the concentration exceeds the threshold

· Integrate high-precision weighing sensors and AI compensation algorithms to dynamically correct the weight deviation caused by material drop

Packaging production line optimization practice

· Change the traditional "series" process to a parallel workstation, and the single-line production capacity is increased to 45 tons/hour

· Configure a pneumatic guide device to shorten the positioning time of ton bag hanging bags from 90 seconds to 12 seconds

· Through the Internet of Things platform, the packaging data is directly connected to the mine ERP system, and the electronic bill of lading that meets international trade standards is automatically generated

Global supply chain supports fast delivery

·80% pre-installed modules were completed by the Vietnam assembly center, and local adaptation to Chile was carried out simultaneously during sea transportation

·Adopting the factory direct sales price model, which is 22% lower than the price quoted by peers

·The technical team completed the on-site foundation pretreatment through AR remote guidance, shortening the construction period by 15 days

Implementation results

·Stability breakthrough: The equipment has been running continuously for more than 2,000 hours in an environment with a dust concentration of more than 120mg/m³, and the failure rate has been reduced by 92%

·Accuracy leap: Dynamic weighing error The margin rate is stable at 0.3%-0.4%, reducing trade claims by $470,000 per year

·Significant efficiency improvement: The average daily processing capacity of a single packaging line has increased from 320 tons to 540 tons, and labor costs have decreased by 65%

Customer Testimonial

"Ply-Pack's customized solution has overturned our perception of 'Made in China'. Its intelligent packaging equipment has not only passed the world's most stringent explosion-proof certification, but also enabled us to seize the market window during the period of copper price fluctuations through the optimization of the packaging production line."-Luis Gonzalez, Production Director of the Chilean Mine

Industry Inspiration

This case confirms Ply-Pack's technical concept: real intelligent packaging equipment must have a deep understanding of the operating scenarios of different industries. From the modular pre-installation of the Vietnamese factory to the equipment base tilt compensation system customized according to the terrain of the mining area, every detail points to the actual benefit growth point of the customer.

At present, the solution has been replicated in 8 overseas projects such as the Zambian cobalt mine and the Indonesian nickel mine, becoming a benchmark paradigm for the intelligent upgrade of mining packaging. Ply-Pack will continue to deepen its vertical fields, so that the factory direct price will no longer be a simple cost advantage, but a value commitment that will benefit global companies from the benefits of technology.