WhatsApp message at two o''clock in the morning, knocking on the door of transformation

In the rainy season of 2023, Ply-pack engineers received a voice message from Dubai, with the background of the muffled sound of the handmade date palm packaging table colliding. "Our old master bends down 2,000 times a day to label, and young people are unwilling to take over." This request for help with an Arabic accent revealed the survival anxiety of a century-old date palm workshop-it must not only keep the ancestral honey-pickled craftsmanship, but also pass the BRC food safety certification within 3 months.

Through 47 WhatsApp video conferences, the Ply-pack team captured two key contradictions:

.The "irregular beauty" formed by hand-made plating is the core of product premium

.Existing commercially available equipment will destroy the crystal structure of the icing on the surface of the date palm

This just confirms the typical dilemma of Middle Eastern food processing companies: standardized production and special processes are difficult to be compatible.

A customized device that can "breathe"

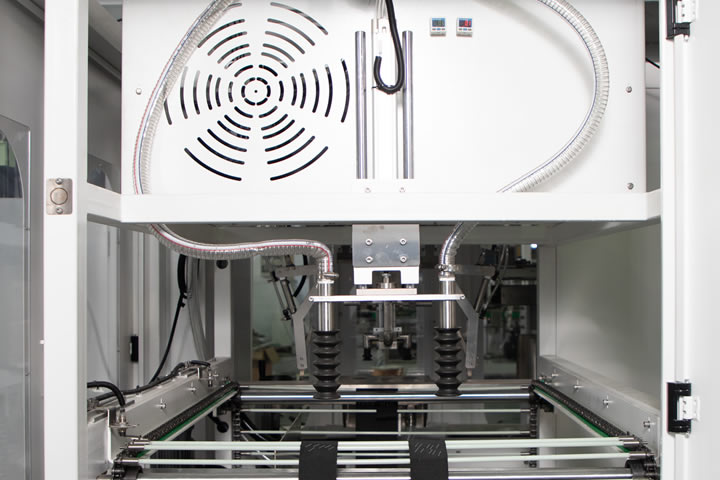

The solution to customer pain points is full of contradictory tension: it is necessary to achieve 90% automation while retaining 10% of the essence of manual labor. The customized food packaging machine finally delivered by Ply-pack has achieved breakthroughs in three dimensions:

·Touch simulation system: The surface of the vacuum suction cup is covered with a bionic silicone layer, and the gripping force simulates the touch of human fingertips

·Dynamic learning module: Through AI visual recognition of the master''s plating rules, an "imperfect aesthetics" database is generated

·Climate compensation device: According to the real-time temperature and humidity of the workshop, the icing solidification time is automatically adjusted to the optimal state

The most eye-catching design of this equipment is that it retains a "manual intervention channel". The master can adjust the swing amplitude of the robot arm at any time, and these operation data will be synchronously entered into the system, becoming the nutrient for the continuous evolution of the equipment.

Technical breakthrough in the sandstorm

Equipment testing in the special environment of the Middle East has evolved into a technical battle. When sand and dust particles cause the conveyor belt to decrease in accuracy, Ply-pack engineers developed a "double pulse cleaning system" overnight-every 30 packaging cycles, the equipment automatically uses compressed air and negative pressure adsorption for double dust removal. This innovation not only reduces the failure rate to 0.3%, but also derives a general module suitable for dried fruits, spices and other fields.

Transformation Revelation

Six months after the project was implemented, this workshop, which was on the verge of withdrawing from the European market, actually received a long-term order from a French luxury food company. Its transformation data is of great reference value in the industry:

·The degree of manual participation has dropped from 100% to 15%, and the production capacity has increased by 5 times

·The packaging standardization compliance rate is 97.2%, while retaining 81% of the handmade aesthetic features

·The equipment investment return cycle is shortened to 14 months

The more far-reaching impact is that this case has promoted the cognitive transformation of the traditional food processing industry in the Middle East. The UAE Food Association included it as a benchmark case of "culturally sensitive smart manufacturing", and the number of similar inquiries received by Ply-pack surged by 300% in three months.

Let machines learn to respect traditions

"The rhythmic sound of the equipment now is as reassuring as the sound of my grandfather hitting the copper mold." The evaluation of the third-generation descendant of the customer revealed another possibility of smart manufacturing - the machine is not a traditional gravedigger, but a inheritor of cultural genes.

Ply-pack is extending this methodology to the fields of fig preserves and camel dairy products, and through the dual engines of "flexible packaging solutions + local adaptation", it helps more small and medium-sized food companies find the golden balance between traditional craftsmanship and smart production. When the sound of mechanical operation sounded in the ancient workshop in the desert, what we saw was not the replacement of manual labor by industry, but a dance of technology across time and space.