Last month, I went on a business trip to a place in East China with the after-sales team. As soon as I entered the customer's workshop, I heard the person in charge, Lao Liu, yelling: "The lotus leaf packaging of this zongzi gift box has stumped our old masters!" Looking closer, the traditional equipment was stuck with half a wrinkled lotus leaf, and the leaked glutinous rice was scattered on the assembly line - this scene gave our small automatic packaging machine an opportunity to show its prowess.

This company that makes traditional food is facing the pain of transformation: it must retain the special-shaped packaging with a handmade feel, and keep up with the explosive pace of e-commerce orders. Our technician Lao Zhang squatted in the workshop and observed for two hours. Suddenly, he clapped his legs and laughed: "Isn't this the test question designed for our small automatic packaging machine!" The next day, we directly transferred an engineering prototype from the factory.

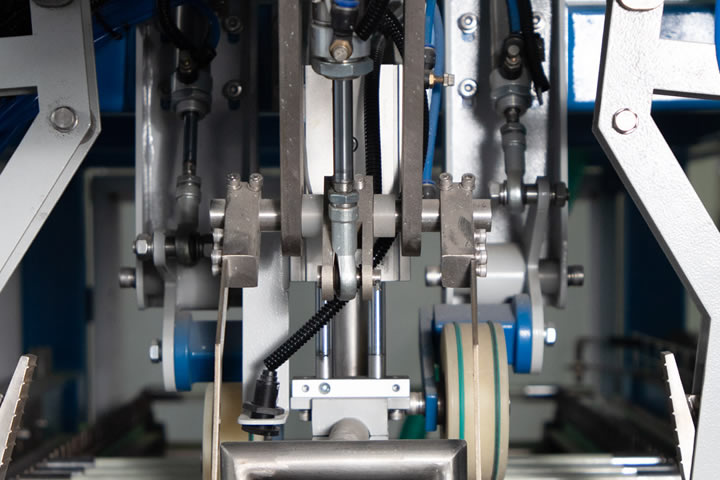

Guess what? The lotus leaf packaging process, which was originally stuck, turned out to be a new trick after being replaced with our small automatic packaging machine. The bionic gripper of the equipment can gently grasp irregular leaves like a human hand, and with an adjustable negative pressure suction cup, even the most tricky special-shaped packaging can be tamed. The workshop director later secretly told me that they used this machine to complete 80% of the gift box packaging for the Dragon Boat Festival order, and the breakage rate was nearly half lower than that of manual packaging.

What's even more amazing is the improvement in production change efficiency. Last week, they received a temporary order for Mid-Autumn Festival mooncake boxes, switching from zongzi leaves to oil paper packaging. Operator Xiao Wang took less than 20 minutes to complete the equipment adjustment. "In the past, it took half a day to change production, but now it's just like changing the theme of a mobile phone." Hearing the customer's analogy, our engineers added a "holiday limited packaging" shortcut menu to the control panel overnight.

The case that makes us most proud is the health food factory in South China. In their 100,000-level aseptic workshop, a small automatic packaging machine is wearing a special stainless steel "protective suit" and is packaging collagen powder. The customer was initially worried about the dust problem of the equipment, so we added a three-stage filtration device to the feeding system, and even designed an air shower purification link for the bag entry channel. Now their quality inspection report shows that the number of particles in the packaging environment is more stable than during the manual operation period.

Recently, there is also a particularly interesting modification case - a pet snack factory in North China wants to use a small automatic packaging machine to process dried meat strips. This thing is irregular and easy to stick, so our technical team has a lot of ideas and added a barbecue-style rotating lever at the discharge port. Now watching the dried meat strips dancing "spinning dance" on the conveyor belt and accurately entering the bag, the customer jokingly calls it "the most fragrant assembly line performance."

Some people may think that small automatic packaging machines can only handle standard products, but last month, the mushroom cooperative in the southwestern mountainous area gave us a vivid lesson. They need to package dry goods gift boxes of different sizes, from 50 grams of tasting packs to 500 grams of family packs, all on the same line. The solution we provide is a modular combination: use standard modules to handle bulk goods during the day, and replace them with special-shaped packaging modules to make limited gift boxes in the evening, so that the equipment utilization rate is directly maximized.

Every time I visit customers, the most common sentence I hear is: "Your equipment looks small, but it is full of tricks!" Just like the problem we helped a coastal aquatic product company solve last year - both maintaining the oxygen permeability of seafood packaging and preventing bag breakage during transportation. We equipped the small automatic packaging machine with a laser punching device and developed a wavy reinforced edge sealing. Now their express delivery complaint rate has dropped by more than 70%.

Standing in the customer's workshop, watching our small automatic packaging machine swallowing and spitting out a variety of goods, I suddenly remembered the words that the factory manager often said: "Good equipment is not about who is bigger, but whether it can get into the customer's business." Now this "Transformer" that can break into the sterile workshop and pack wild dry goods is not a smart partner that grows in line with customer needs?

Next time if you meet a boss who says "small machines can't do delicate work", you have to ask him to look at these cases: from the rice dumpling gift box with the fragrance of lotus leaves to the medical beauty products with metallic luster, which one is not a technical poem written by a small automatic packaging machine?