When packaging becomes a core competitiveness

In Ho Chi Minh City during the rainy season in 2023, the general manager of a local coffee brand showed us a set of contradictory data: its e-commerce channel monthly sales increased by 300%, but the return rate of offline supermarkets was as high as 18%. The diagnosis found that traditional flat bag packaging was deformed by moisture during transportation, and the upgraded fresh-locking vertical bag faced the dilemma of incompatibility with existing equipment. This typical case reveals the essence of the current growth in demand for packaging machinery-packaging has evolved from an auxiliary process to a key factor in determining market competitiveness.

Technical reconstruction for three-dimensional breakthrough

After going deep into the production site, the Ply-Pack special team found that the real pain points of customers are:

- 6 hours of manual adjustment required for switching between 12 bag types

- The qualified rate of nitrogen filling fluctuates between 63% and 78%

- Existing equipment is completely unable to read new bio-based film materials

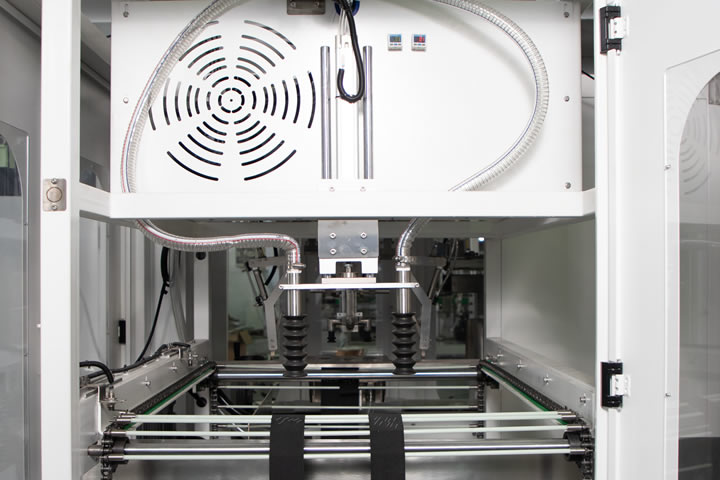

The multimodal packaging central system we proposed breaks the traditional design logic:

- Dynamic mold matrix: The magnetic module group is used to compress the bag type switching time to 18 minutes

- Laser spectrum detection: Real-time monitoring of nitrogen filling purity, controlling the fluctuation range to ±1.5%

- Material self-learning module: Automatically adapt to new environmentally friendly film materials through machine learning models of 2000+ materials

During the trial operation stage of the equipment, an accident verified the reliability of the system-when the sugarcane fiber film temporarily purchased by the customer had a 15% thickness deviation, the equipment automatically triggered the pressure compensation mechanism, so that the sealing qualified rate was stabilized at 99.2%.

48-hour cross-time zone attack

The real test comes from the sudden marketing demand of the brand: in order to seize the Christmas market, the new equipment is required to produce 50,000 sets of limited edition gift boxes simultaneously during the debugging phase. Ply-Pack launched the Global Supply Chain Optimization Emergency Plan:

- Qingdao factory assembled core modules overnight

- Malaysia warehouse allocated compatible accessories

- German technical center remotely calibrated the visual system

It took only 52 hours from receiving the demand to the first batch of finished products coming off the line, which is 83% shorter than the conventional process. Behind this responsiveness is the intelligent capacity cloud map system we built, which is in real time docking the inventory status of 187 key components in 7 major warehouses around the world.

The butterfly effect of the packaging line

After the new production line was put into production, a chain of commercial reactions occurred:

- The shelf life was extended from 6 months to 9 months, advancing into high-end supermarkets in Europe

- The three-dimensional bag type reduced the shelf area by 40% and increased the distribution rate

- AR interactive packaging led to a 27% increase in repurchase rate

What is more exciting is that with the help of this customized production line, customers successfully increased the product premium by 34%. As its operations director said during the acceptance: "This is not a simple equipment purchase, but the ability to continuously create market differentiation."

Continuous empowerment of the smart manufacturing ecosystem

Project delivery is not the end, Ply-Pack's Equipment Health Perception System continues to output value:

- Optimize the best energy consumption curve by analyzing 11 months of production data

- Warn about bearing fatigue loss to avoid unplanned downtime

- Automatically push the latest environmentally friendly packaging regulations adaptation plan

When the brand recently launched the North American market expansion, the original production line only needed 72 hours of software and hardware upgrades to meet the new FDA regulations. This continuous evolution capability is the deep value of smart manufacturing upgrades-making each device a growing life form.