Last month, I received an urgent call from Mr. Zhang, an old customer. The voice on the other end of the phone was eight degrees higher: "Send someone to take a look! The new eye cream aluminum tube production line leaks three out of ten tubes, and the return barrage in the live broadcast room is almost flooding the screen!" After hanging up the phone, I rushed to the high-speed rail station with a tool box - the complaint about cosmetic packaging machine leakage is really an emergency that will ruin the brand.

The scene was like a "tear production line"

When we arrived at the workshop, the assembly line was spitting out "tear-marked tubes": some tube shoulder welds were like untightened faucets, and some tail seals were oozing crystal paste. I picked up a leaking tube at random, and the heat-sealed part was still burred. Operator Xiao Wang said with a bitter face: "This batch of new packaging machines has a bad temper. After adjusting the parameters for three days, it is still sometimes good and sometimes bad."

We disassembled the machine for inspection overnight and found that the root cause was in two places: first, the traditional sealing detection relies on pressure sensing, which is confused when the thickness of the aluminum tube is uneven; second, the heat sealing head is too "straight" and the tube body is slightly tilted and pressed hard, just like using a hammer to smash tofu.

Equip the machine with "intelligent touch"

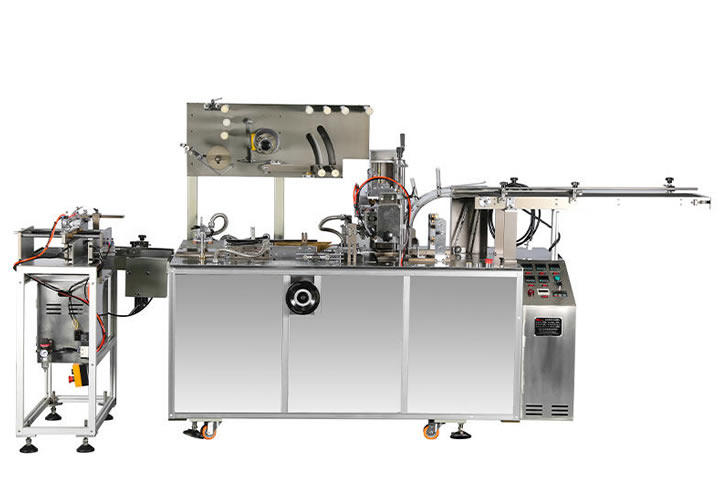

Immediately after returning to the factory, the technical team held a meeting, and everyone decided to perform a "neurosurgery" on the cosmetics packaging machine:

1. Upgrade the sealing detection algorithm: abandon the old single-point pressure detection and use carpet-style infrared scanning instead. This system can draw a heat map of the density change of each millimeter of the weld, just like checking a CT scan. During the test last week, even the hair-thin cracks did not escape its "eagle eyes".

2. Adaptive heat sealing temperature: We have developed a temperature control module that can "read the words and see the color". If the tube is thin, it will automatically drop 5℃, and if the material is hard, it will instantly increase 10℃. It is more stable than the hand feeling of the old master. During a test, technician Xiao Liu deliberately mixed aluminum tubes from different batches, and the machine actually adjusted the golden temperature zone by itself.

3. Automatic deviation correction system: This thing can be called the "traffic police" of the production line. If the tube body deviates by more than 0.3 mm, the two rows of pneumatic claws will immediately straighten it; if the speed difference of the rotating table exceeds the critical value, the deviation correction wheel group will instantly become an "anti-shake gimbal". The last time I went to debug the emulsion filling line, the director of the customer's workshop said: "This technology should go to the mobile phone factory to grab a job!"

"The Battle of the Gods" at 3 a.m.

The night I returned to the customer's workshop after the transformation, it was just in time for the deadline for the big sale. The new system gave us a warning as soon as it was launched - the automatic correction system suddenly reported an error, and more than 20 tubes were stuck on the conveyor belt and danced "hip dance".

Several old masters surrounded the control screen to check the code. I picked up a flashlight and got under the equipment and found that the dust cover of the visual sensor was stained with oil. After wiping it with alcohol cotton, the production line suddenly seemed to be turned on: aluminum tubes lined up and slid into the workstation, the heat sealing head rose and fell like a timer, and the weld of the finished tube was as smooth as laser cutting.

When the first inspection report came out at 3 a.m., Mr. Zhang's hand holding the yield rate report was shaking: "99.2%! It's a total turn over compared to before the transformation!" What's more amazing is that the new system generates a traceability code for the process data of each tube. You can know which tube was produced on which day and which batch by scanning the code.

The live broadcast room barrage turned into "rainbow fart"

Three months later, when I visited again, the big screen in the workshop was showing the brand live broadcast room. The anchor took the modified eye cream tube and shook it: "Family members, watch it! It won't leak even if it is made this way!" The barrage passed by "domestic packaging ceiling" and "obsessive-compulsive disorder cure artifact". Mr. Zhang said that the daily production capacity has increased by 30%, but the customer complaint rate has dropped by 80%. Even the OEM factory came to ask which cosmetics packaging machine was used.

Last week, their R&D department also gave us a new problem: Can an AI learning module be added to the automatic deviation correction system? They said they wanted to be compatible with special-shaped tube packaging. The guys in the technical group got excited when they heard it, and they are now soaking in the laboratory to chew on the algorithm!

Workshop Notes:

This battle against complaints about cosmetic packaging machines leaking liquid has reminded us that the more sophisticated the packaging material, the more it needs a "coarse yet fine" solution. From intelligent detection to dynamic deviation correction, behind every technological breakthrough is the persistence of eating instant noodles with a multimeter late at night. Next time you see a tightly sealed cosmetic tube in the mall, take a closer look - it may be a "work of art" sealed by our factory's equipment!