Last week, when I took customers to visit our newly completed intelligent packaging center, Mr. Wang, who makes maternal and child products, suddenly pointed at the assembly line and shouted: "Look! The box of dolls and glass milk bottles are actually sorted into the same lane!" Before I could explain, the robotic arm on the conveyor belt had already steadily completed the box closing - the puffy toys were at the bottom, the fragile items were at the top, and the packaging film just wrapped around three and a half circles.

Who would have believed this scene three years ago? At that time, the biggest headache for cross-border e-commerce customers was mixed orders ranging from lipsticks to tents.

“Does your system have eyes?”

When we renovated the warehouse of a hypermarket in Hangzhou last year, their operations manager Lao Zhang squatted in front of the equipment and pondered for a long time: “How can your smart packaging center fit five more items in the same carton?” I smiled and lifted the dust cover of the dynamic volume measuring instrument: “This thing is more poisonous than human eyes, even the void ratio of foam filling can be calculated.”

It sounds simple, but our technical team drank refreshing drinks for three months just to let the scanning head recognize the appearance of 100,000 kinds of goods. Now this system can automatically plan the stacking order according to the softness and hardness of the goods. Last month, the container space utilization rate of the down jacket + ceramic cup order sent to Northern Europe was increased by 30%.

The “strongest brain” of the smart packaging center

This spring, the warehouse explosion crisis of Shenzhen customers made us sweat. With an average of 20,000 cross-border small packages per day, the original assembly line has been stuck like a PPT. Our engineers were on-site for 72 hours and installed a "prediction system" for the smart packaging center:

· When the scanner reads the "liquid" label, it will automatically divert to the leak-proof packaging line

· When encountering 10,000 orders of the same product during the promotion season, the batch laminating channel will be started

· When the robot grabs a special-shaped package, it will "weigh" the center of gravity like a human

The most amazing thing is the self-learning algorithm. During the inspection last week, it was found that the system actually figured out the "bagging first and then boxing" special process for the rainy season in Southeast Asia-it was later discovered that it was based on customer return data within three months.

From "people chasing goods" to "goods waiting for people"

At the end of last month, we organized a complaint conference for customers. Sister Li, who works in the Southeast Asian market, said it honestly: "In the past, the packers were busier than the couriers on Double Eleven. Now, wherever the light strips in the smart packaging center flash, the material frame follows, and the little girl can supervise in high heels."

Although this is exaggerated, it hits the pain point. The scene of workers chasing packages in traditional warehouses has completely disappeared in the smart packaging center designed by us. Now, each workstation only needs to be refilled when the light is on, and the robot arm will even automatically adjust the height of the operating table according to the height of the employee.

The "system rebellion period" at 2 a.m. Of course, revolutions are not always smooth. I remember that in the first week of the system going online, I received an emergency call from a customer at 2 a.m.: "Your robot packed children's bicycles and bikinis together!" Our technical director Lao Chen led the team to the scene and found that the swimsuit label was mistakenly identified as "outdoor equipment".

That night, the warehouse became a temporary laboratory. Later, we added an "ethical logic layer" to the algorithm. Now when encountering children's clothing products, the system will automatically avoid the adult product partition - this detail has made many cross-border maternal and child customers our die-hard fans.

Conclusion

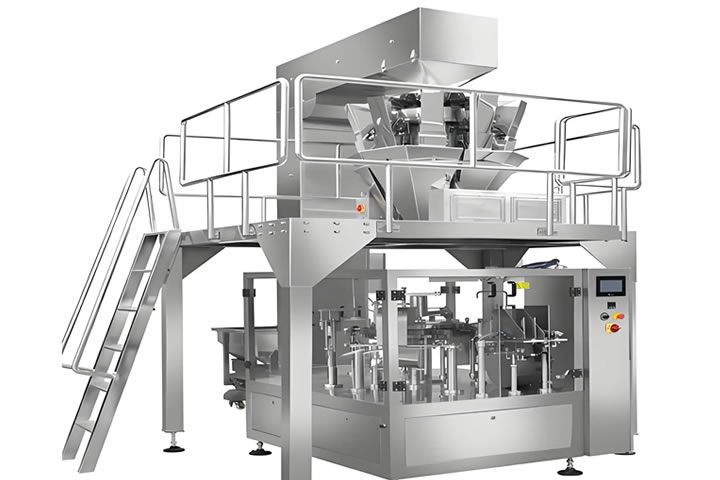

Now when you walk into the intelligent packaging center of a cooperative customer, you can often see interesting pictures: a post-00 operator holding a tablet to adjust parameters, a 20-year-old master wearing AR glasses to do equipment inspection, and our factory's packaging machine is like a living building block, automatically changing modules to cope with the surge in orders.

Next time you see a cross-border e-commerce package that is particularly tight and square, it may be the work of our intelligent packaging center. By the way, I heard that next month we will make an antifreeze system for a Russian customer, and lubrication technology that can operate normally at minus 30 degrees Celsius - this is enough for our technical department to drink three more boxes of Red Bull!