Last month, Mr. Wang from a toy factory in Dongguan came to inspect the equipment. He stared at the assembly line for half an hour, and suddenly took out his mobile phone to shoot a video and sent it to his circle of friends: "I have waited for the packaging effect for ten years, and finally let my old friend make it!" In the video, crooked dinosaur toys lined up to get into the packaging box, and each one was as straight as the National Day military parade - this is enough for our workshop to brag about for half a year!

The story started last fall. Mr. Wang pulled our technical director Lao Li to complain: "You said that toys are getting weirder and weirder now, Tyrannosaurus Rex has movable joints, and robots can be transformed! My packaging line is criticized by customers every day for "selling dog meat under the guise of sheep" - the display picture is the front face, and when it is disassembled, it is all the back of the head!" This remark really touched our hearts, and we immediately set up a research team to cure this "wrong neck disease in packaging"!

What is the secret of this 3D visual positioning system?

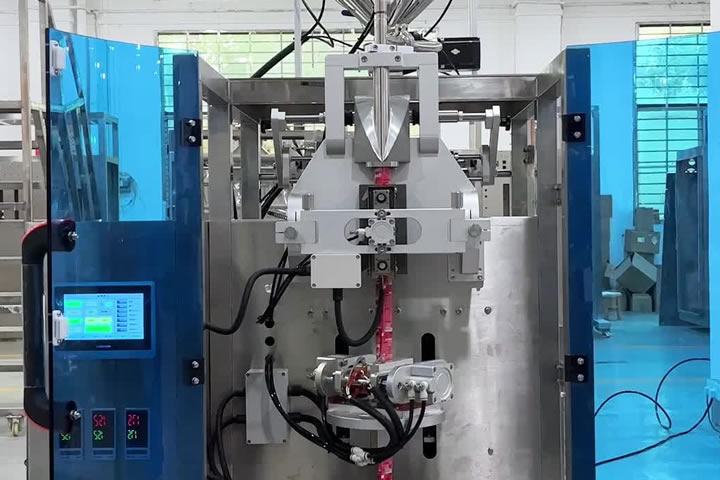

In short, it is "three tricks": scan first, calculate later, and then grab. We installed a circular scanning array for the visual positioning packaging machine. No matter what S-shaped curves or special-shaped products you have, you can build a 3D model in one turn. Last week, we debugged the model factory in Zhejiang, and even the exposed hydraulic pipes of the mecha warriors were accurately identified, and the positioning accuracy was 30% more accurate than manual visual inspection!

The most amazing thing is the intelligent deviation correction technology. The system will compare the actual object with the packaging design drawing and automatically calculate the best angle for entering the box. Guess what? Last month, a Qingdao customer packaged a winged elf figurine. The system changed the 45° side-flying shape to a front-facing photo with wings spread. The girl in the customer's marketing department exclaimed that "it can pose better than an artist"!

Actual cases are better than instructions

In the early spring of this year, a toy factory in Guangdong received a large overseas order - an alien spaceship that glows and transforms. Seeing that the delivery date is approaching, the packaging qualification rate is still stuck at around 70%. We shipped the visual positioning packaging machine overnight, and taught the robot arm to "gentle grasp" during the three-day debugging period. Now on the packaging line for special-shaped products, the flexible gripper device is like an air cushion for the toys, and the degree of delicateness is comparable to the handling of museum artifacts.

Another unexpected gain: this system has a built-in "learning evolution" function. After processing more than 300 toys, it can automatically match historical data when encountering similar shapes. Mr. Wang's workshop now changes packaging, and the debugging time is reduced from 4 hours to 40 minutes. The old masters can finally get off work on time to pick up their grandchildren!

The operation is so simple that even interns can play with it

Are you worried about the high threshold of new technologies? We have already made the complex procedures "idiot-proof"! The control screen is like a smart phone - click on the product library to select the model, aim at the positioning frame and press scan, and the rest is left to the visual positioning packaging machine. At the Beijing exhibition last month, a college student temporary worker operated on site and packed more than 20 special-shaped samples in half an hour, which surprised the purchasing manager and gave him a thumbs up.

Maintenance is also worry-free: blow the lens with an air gun every week, and do a calibration test every month. We added a self-cleaning device to the scanning area, so we are not afraid of "eyes blinding" no matter how much dust there is. There was a heating pipe in the workshop of a northeastern customer, and the system worked as usual. The customer jokingly called it "the best guy with the best eyesight in smog days"!

There will be more things to do in the future

I heard that the "opening box ritual" is popular in the trendy toy circle now, and our laboratory is developing AR linkage functions. Imagine: the mobile phone scans the packaging box, and the toy 3D display animation pops up immediately - this technology has been tested by Shanghai customers, and it is said that the pre-sale volume has increased by 30%! Next month, we will also install pressure sensors on the blind box production line of Hangzhou customers to ensure that each irregular product package cannot shake out the content prompt.

Looking at the comparison pictures sent by customers - the left side is a crooked "car accident scene", and the right side is a neat and uniform "review square", I feel so happy! If you encounter the trouble of irregular product packaging one day, come to the workshop for tea at any time. Our 3D visual positioning system is specially designed to cure all kinds of dissatisfaction!

(Rumor: This system can be used to install medical equipment and handicrafts by changing the parameters...)