I. Product core positioning

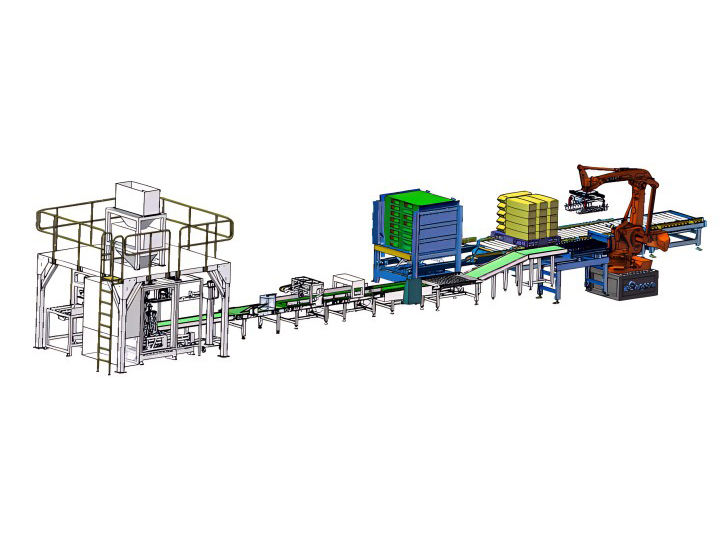

Fully Automatic Packaging And Palletizing Production Line is an efficient solution developed by Fly-Pack Factory for the integration of full-process packaging and intelligent palletizing. It is suitable for batch processing of boxed, bagged and bottled products in the food, pharmaceutical, electronics and other industries. Fully Automatic Packaging And Palletizing Production Line integrates the entire process of packaging → testing → palletizing → warehousing and logistics. The single-line processing speed reaches 240 boxes/minute. It is compatible with packaging materials such as cartons, shrink films, and environmentally friendly pallets. The palletizing accuracy error is ≤±0.5mm. It supports multi-specification mixed loading and synchronous operation of special-shaped products, significantly improving production efficiency and standardization level.

II.Core technical advantages

Intelligent collaboration and dynamic optimization

Fully Automatic Packaging And Palletizing Production Line uses AI visual positioning system and Industrial Internet of Things (IIoT) technology to analyze product size (20-800mm) and stacking mode in real time, dynamically adjust the robot arm path planning, and realize accurate grasping and layered stacking of special-shaped products such as glass bottles and soft packaging24. The servo drive system is combined with dynamic weight compensation technology, and the single stack weight error is ≤±2kg, which meets the high-precision requirements of pharmaceutical cold chain, food export, etc.

Multi-scenario adaptation and flexible expansion.

·Packaging material compatibility: Fully Automatic Packaging And Palletizing Production Line supports corrugated boxes (thickness 0.5-5mm), PE shrink film and degradable pallets, intelligent sealing temperature adjustment (70-200℃), sealing strength ≥50N/cm², and is suitable for high-temperature sterilization and low-temperature storage environments.

·Modular design: Fully Automatic Packaging And Palletizing Production Line can expand metal detection, coding traceability, and online weighing modules, complete production line configuration switching within 5 minutes, and support mixed loading mode (such as 24 bottles + promotional card combination). .

Energy-saving and efficient and clean production

·Energy consumption optimization: The dual-channel parallel operation of the Fully Automatic Packaging And Palletizing Production Line reduces power consumption by 30%, and the intelligent standby mode saves more than 15,000kWh per year.

·Safety protection: The Fully Automatic Packaging And Palletizing Production Line is equipped with a dust-free filling cabin (dust concentration ≤ 0.1mg/m³) and a food-grade stainless steel body, which complies with GMP and ISO 22000 standards; the infrared grating + emergency stop system ensures high-speed operation safety.

III. Industry application scenarios

The Fully Automatic Packaging And Palletizing Production Line achieves efficient production in the following fields with high flexibility and stability:

·Food and beverage: Automated palletizing of canned drinks and frozen foods, supporting flexible configuration of 6-48 pieces/pallet, and stacking height of up to 2.5 meters.

·Pharmaceutical industry: Full-process packaging of drug boxes and instructions, supporting batch traceability code printing and clean room environment certification. · Electronic manufacturing: Shockproof pallet stacking of mobile phone accessories (charger + data cable), with up to 12 layers of stacking and positioning error ≤±1mm.

IV. Technical parameters and configuration

|

Item |

Parameter/Function |

|

Processing speed |

200-240 boxes/minute (dual-channel synchronization) |

|

Applicable pallet size |

Length 800-1200mm×Width 600-1000mm×Height 1000-2500mm |

|

Palletizing accuracy |

±0.5mm (AI dynamic correction system) |

|

Power requirement |

380V/50Hz, power ≤25kW |

|

Overall machine size |

9000×4500×5500mm (304 stainless steel body) |