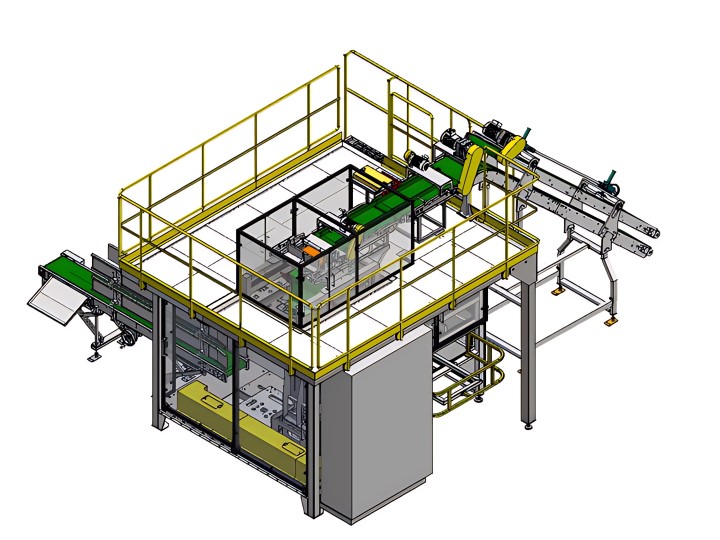

The energy-saving Secondary Packaging Palletizing, innovatively developed by the fly pack factory, is specifically designed for the recyclable packaging bags of FFS Packaging Machines. Through servo drive and modular architecture, it reduces energy consumption by 30% and achieves a 98% pallet space utilization rate of 34. The equipment adopts a patented clamp centering mechanism to accurately grasp the biodegradable PE bags and paper plastic composite bags produced by FFS equipment, avoiding the waste of environmentally friendly materials caused by packaging damage.

Core advantages

Empowering Green Production:

When working in collaboration with FFS Packaging Machine, the system obtains the type of packaging material (such as recyclable PE film, biobased materials) through the MES platform, automatically switches the gripping force and stacking strategy, and reduces the friction loss of packaging bags by 23. The device body is made of 80% recyclable steel, with an operating noise level of ≤ 65dB, and complies with ISO 14001 environmental certification 24.

Intelligent energy management:

Integrated dual-mode energy control system, automatically switches to standby mode during intermittent discharge periods of FFS equipment, reducing ineffective energy consumption. Actual test data shows that the 24-hour production line linked with FFS Packaging Machine can save 120kW · h 34.

Flexible expansion capability:

Equipped with a detachable gripper compartment, the switch between FFS square bottom valve bag and M-type PE bag can be completed within 10 minutes, adapting to the multi category production needs of the chemical and daily chemical industries. By using laser marking technology, the FFS packaging information is bound to the pallet ID to achieve full process traceability management.

Technical parameters

Energy consumption index: 22kW (standard mode)/15kW (energy-saving mode)

Material compatibility: PE film, biodegradable plastic, paper plastic composite material

Expansion interface: supports seamless integration with FFS equipment and AGV conveyor systems

Environmental certification: ISO 14001, CE, RoHS 24