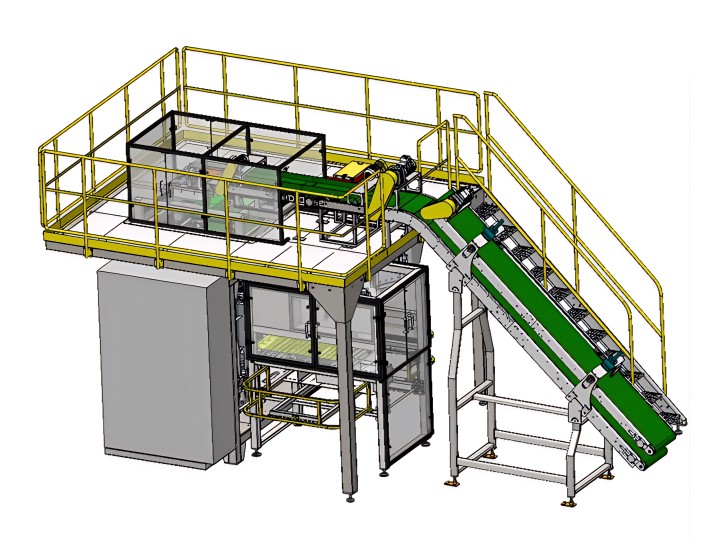

The dynamic correction type Secondary Packing Palletizing launched by the ply pack factory is specially designed for optimizing the post-processing of FFS Packaging Machines. It integrates the Blue Fat DeStuff IT power transmission system and special suction cup gripper technology to achieve full process automation of unloading, container sorting, and palletizing. The device scans the barcode information of the FFS packaging bag (compatible with PE heavy film bags and upright bags sealed by FFS equipment), matches order data in real time, and plans the stacking structure to ensure that the stacking error of each layer is ≤ 1.5mm.

Core advantages

Dynamic stacking adaptation:

By using 3D visual scanning and AI dynamic correction algorithm, the irregular packaging bag shape output by FFS Packaging Machine can be recognized, and the grasping angle and stacking path can be automatically adjusted to adapt to multi size boxes and complex storage needs. The system supports single SKU pallets and mixed stacking types, with a processing capacity of 700 boxes per hour, which is four times more efficient than traditional manual labor.

Seamless production line collaboration:

Real time data exchange between OPC-UA protocol and FFS Packaging Machine is used to synchronously obtain packaging specifications, material weight, and other information. The conveyor belt speed and robotic arm stroke are dynamically adjusted to achieve a 35% increase in overall production line beat matching. For the high-speed discharge scenario of FFS equipment (≥ 2000 packages/hour), this system is equipped with a dual servo driven buffer platform to effectively avoid the risk of material blockage.

Adaptation to clean environment:

For the food and pharmaceutical industries, the equipment is equipped with ion air cleaning modules and stainless steel protective covers to ensure that the entire process of FFS packaging bags, from sealing to palletizing, complies with GMP cleanliness standards and prevents cross contamination. Simultaneously supporting operation in a -10 ¡æ low-temperature environment, compatible with FFS frozen food packaging lines.

Technical parameters

Processing speed: 45 boxes/minute (standard box)

Stacking error: ± 1.5mm

Compatible specifications: 5-50kg packaging bags produced by FFS equipment

Energy consumption: 15kW (reduced by 30% in energy-saving mode)