I. Core product positioning

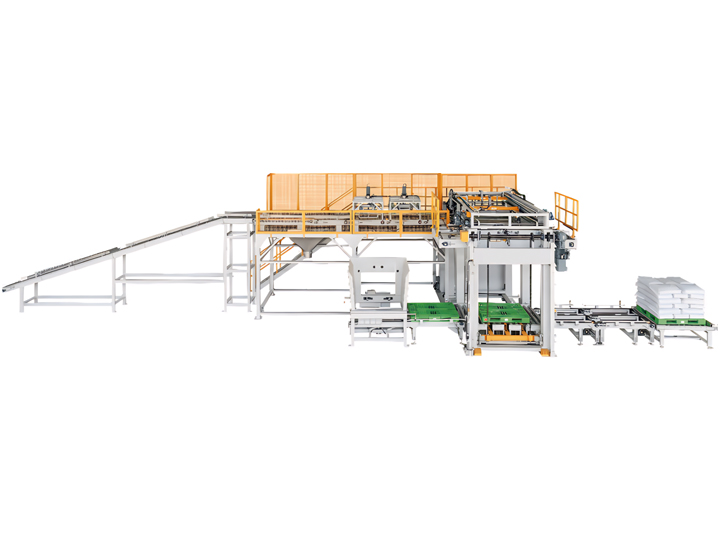

High-Performance High Position Palletizer is an intelligent high-position palletizing device designed by ply-pack factory for high-speed production lines and large-capacity storage needs. It is specially designed to provide efficient stacking solutions for regular packaging such as cartons, woven bags, and barreled materials. High-Performance High Position Palletizer equipment supports seamless connection with front-end production lines (such as filling and sealing machines). The processing speed of a single machine reaches 60 boxes/minute (cartons) or 28 bags/minute (bagged materials). The stacking height is ≤1.8m, which is suitable for the high-intensity production needs of petrochemical, food, medicine, building materials and other industries.

II. Core technical advantages

High-position high-speed stacking and flexible lane division

High-Performance High Position Palletizer adopts servo lane division technology and linear encoding system, supports multi-lane box division (up to 8 lanes) and multi-pallet type switching (such as tic-tac-toe type, rotating staggered type), and can adapt to different box types and stacking modes without mechanical adjustment. The positioning accuracy of the box body is ±1mm, and there is zero impact during the grasping process.

Intelligent Vision and Precision Control

Visual Positioning System: High-Performance High Position Palletizer uses 3D vision to identify the size and position of the box, automatically optimizes the grasping path, and solves the misalignment problem of special-shaped packaging (such as cosmetic gift boxes and medicine bottle groups);

Multi-axis Collaborative Control: High-Performance High Position Palletizer integrates 6-axis joint robot arms and high-precision servo motors, with a grasping load of ≤50kg and a repeat positioning accuracy of ±0.5mm.

Energy Saving and Operation and Maintenance Optimization

Low Power Design: High-Performance High Position Palletizer has a power consumption of ≤1.5kW in intelligent standby mode, saving more than 15,000kWh per year;

Fault Self-diagnosis: High-Performance High Position Palletizer displays abnormal codes (such as robot arm overload, conveyor belt jam) in real time through the HMI interface, improving maintenance efficiency by 40%.

III. Industry application scenarios

The High-Performance High Position Palletizer is widely used in the following fields due to its high speed and high compatibility:

Food industry: 60 cartons/minute beverage carton palletizing, supporting high-line conveying and AGV linkage; Medical field: pharmaceutical aluminum-plastic panel stacking, in line with GMP clean workshop standards; Building materials industry: 50kg dry-mixed mortar bag automatic palletizing, suitable for continuous production lines.

IV. Technical parameters and configuration

|

Item |

Parameter/Function |

|

Processing speed |

60 boxes/minute (carton), 28 packs/minute (bag) |

|

Stacking height |

≤1.8m (maximum load 1,000kg) |

|

Positioning accuracy |

±0.5mm (visual system) |

|

Power requirement |

380V/50Hz, power ≤20kW |

|

Machine size |

6500×3500×4200mm (304 stainless steel body) |