Last summer, our factory received an emergency call-a home appliance company's overseas orders were facing huge claims due to excessive packaging damage rate during transportation. When I rushed to the customer's workshop, the pile of damaged cartons in front of me made me feel nervous: "The traditional packaging model really can't keep up with the times." It was this crisis that gave birth to the full implementation of our factory's fully automatic buffer packaging technology.

Pain point hit: Why does traditional packaging always "fall off the chain"?

Everyone who has worked in the packaging industry knows that traditional methods such as manual boxing and foam filling seem to be low-cost, but in fact they have hidden dangers. Customer feedback data shows that the packaging damage rate of their products in cross-border transportation has long been hovering at a relatively high level in the industry, and problems such as scratches on the shell of precision instruments and broken glass panels have occurred frequently.

"We have tried thicker cartons and more expensive foam, but the manual packing force is uneven, and the filling of cushioning materials depends entirely on the feel of the master." The customer's production supervisor, Lao Chen, pointed to the assembly line and shook his head. This common problem in the industry made us realize that to cure the packaging damage rate, we must shift from "human defense" to "technical defense."

The key to breaking the deadlock: the implementation of fully automatic cushioning packaging technology

Back at the factory, the technical team held three brainstorming meetings overnight. The consensus reached by everyone is very clear: the core of cushioning packaging lies in precise adaptation - products of different weights and shapes require differentiated cushioning solutions, and manual operations always have volatility.

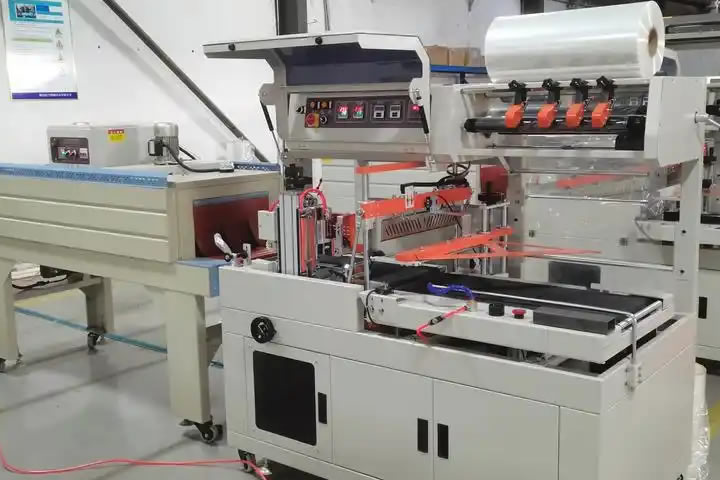

Two months later, the first generation of fully automatic cushioning packaging technology independently developed by our factory officially entered the testing phase. This system automatically identifies product dimensions through three-dimensional scanning, calculates the stress points in real time, and then uses high-pressure airflow to shape the degradable cushioning material into a customized bracket. I still remember that when the machine was first tested, technician Xiao Liu stared at the equipment and muttered to himself: "This machine 'understands' the product better than the hands of the master!"

Actual test: Cross-border counterattack from home appliances to fresh food

The first prototype was quickly delivered to the home appliance company. Surprisingly, the fully automatic cushioning packaging technology not only solved their transportation damage rate problem, but also brought unexpected gains:

Precision instruments: The cushioning bracket fits the product surface perfectly, avoiding the static damage caused by traditional foam friction;

Glass panel: The material resilience reaches the industry's high-quality level, and the simulated drop test is zero fragmentation;

Storage cost: Customized filling reduces the amount of cushioning material by about 40%, and the carton volume is optimized simultaneously.

What makes us even more proud is that this technology later shines in the field of fresh cold chain. After a certain aquatic product export company adopted the fully automatic cushioning packaging technology, the survival rate of swimming crab transportation increased to the industry-leading level. "In the past, each box had to be padded with two layers of ice packs. Now, the buffer layer automatically generated by the machine can not only fix the crab legs, but also reserve a low-temperature airflow channel." The customer warehouse manager gestured excitedly during the return visit.

Technical core: dual drive of intelligent algorithm + environmentally friendly materials

Many people ask us, what is the core competitiveness of fully automatic buffer packaging technology? In my opinion, the answer is hidden in two details:

Intelligent learning system: The equipment will remember each packaging data, and automatically call the best solution when encountering similar products, just like building a "buffer file" for each product;

Sustainable materials: The starch-based buffer particles specially developed by our factory will naturally decompose in 24 hours when exposed to water, solving the problem of traditional foam pollution.

Last winter, this set of technology helped a daily chemical customer of ours win the admission qualification for high-end supermarkets in Europe. "The EU audit team originally had strict requirements on the environmental protection of packaging, but when they saw our fully degradable buffer material and intelligent filling report, they gave a thumbs up on the spot." The customer's quality inspection director said this when he clinked glasses with us at the celebration banquet.

The future is here: Make every package "smarter"

Now when you walk into our factory's display workshop, you can see that the third-generation fully automatic buffer packaging technology has achieved "one machine with multiple functions" - the same device can handle 0.5kg cosmetic bottles and pack 25kg industrial parts. Recently, we are also experimenting with IoT upgrades, planning to generate a unique QR code for each buffer bracket, so that customers can scan the code to view the packaging force record, truly realizing the transparency of the transportation process.