I. Product Core Positioning

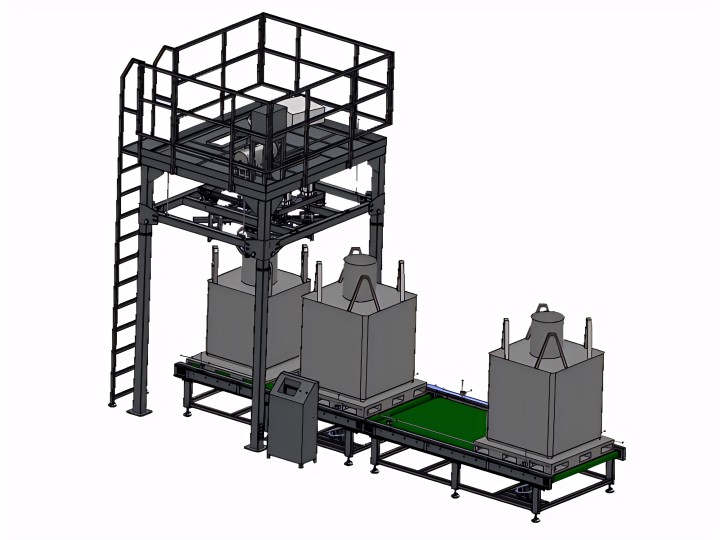

Bulk Bag Packing Machine is a fully automated equipment designed by Ply-Pack Factory for large-capacity bulk material packaging. It is suitable for the packaging needs of 500-2000kg particles, powders and loose materials in the chemical, building materials, agriculture, food and other industries. Bulk Bag Packing Machine uses prefabricated ton bags (space bags), integrating the full process of automatic bagging → precise filling → sealing → palletizing. The packaging efficiency is up to 40 bags/hour, supporting a single bag load of 2 tons, significantly reducing labor costs and packaging material losses.

II. Core Technology Advantages

1. Full process automation and high precision

Bulk Bag Packing Machine controls the filling speed and metering accuracy (±0.2%) through the intelligent PLC system, and is equipped with a double-station rotating platform to achieve continuous operation. It is suitable for materials with poor fluidity such as mineral powder, cement, and feed. The servo drive and pneumatic clamp ensure that the positioning error of the ton bag is ≤±5mm and the sealing strength is ≥50N/15mm, ensuring the safety of long-distance transportation.

2. Modular design and flexible adaptation

Multi-specification compatibility: Bulk Bag Packing Machine supports 500-2000kg bag type, bag opening size 200-600mm, and is suitable for PE woven bags, anti-static ton bags and other materials.

Dust control: Bulk Bag Packing Machine has a fully enclosed filling port + negative pressure dust removal system, which reduces the dust overflow rate by 95%, meets GMP clean standards, and is suitable for pharmaceutical raw materials and corrosive chemical packaging.

3. Intelligent safety and efficient cost reduction

Bulk Bag Packing Machine is equipped with overload protection, abnormal bag weight alarm and one-button type change function, supports remote monitoring and data traceability; the double-station stacking system improves stacking efficiency by 30%, and the daily output of a single machine can reach 300 tons.

III. Industry Application Scenarios

Bulk Bag Packing Machine has excellent performance in the following fields with its high load, dust-proof and corrosion-resistant characteristics:

·Chemical Industry: Large-capacity sealed packaging of polyethylene granules, resin powder, and fertilizers, suitable for leak-proof filling of corrosive materials.

·Building Materials Industry: Efficient filling of cement, mineral powder, and dry-mixed mortar, with a single bag load of up to 2 tons and stacking stability increased by 50%.

·Agricultural Field: Moisture-proof and mildew-proof packaging of feed, grains, and seeds, supporting outdoor storage environments.

·Food Industry: Clean and dust-free packaging of sugar, salt, and starch raw materials, in line with HACCP hygiene standards.

IV. Technical Parameters and Configuration

|

Item |

Parameter/Function |

|

Packing capacity |

500-2000kg (3000kg super-large ton bags can be customized) |

|

Packing speed |

30-40 bags/hour (double-station synchronous operation) |

|

Measuring accuracy |

±0.2% (dynamic weighing system) |

|

Power requirement |

380V/50Hz, power 7.5-15kW |

|

Machine size |

6500×4000×5500mm (stainless steel body) |